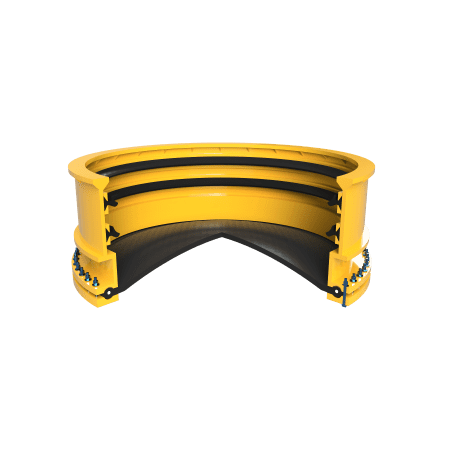

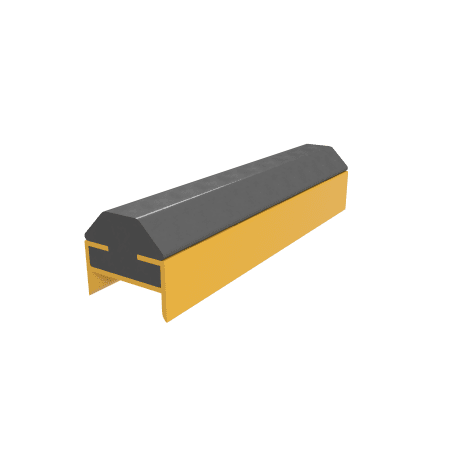

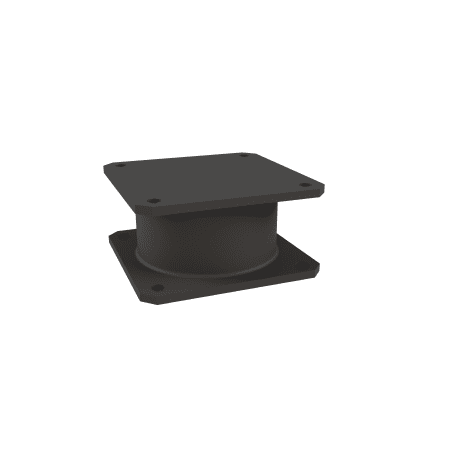

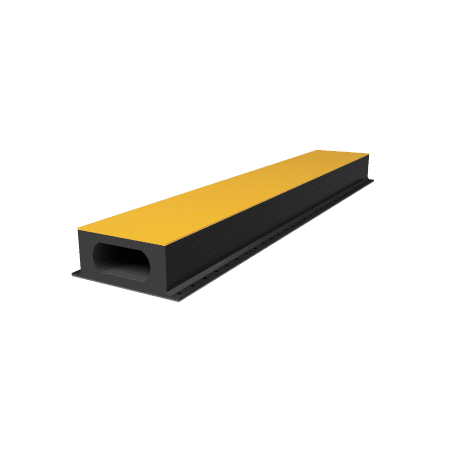

Hitech leg mating units are an integral part of an offshore floatover operation. During a floatover operation, the barge is positioned over the jackets legs with LMU already welded to either the jacket leg or the topside legs. the LMU receptor cone is positioned over the receptor cone and then ballasting is done to lower the topside on the legs. this process is time-consuming and done in open sea, therefore, the LMU absorb the vertical as well as horizontal loads of the topside.

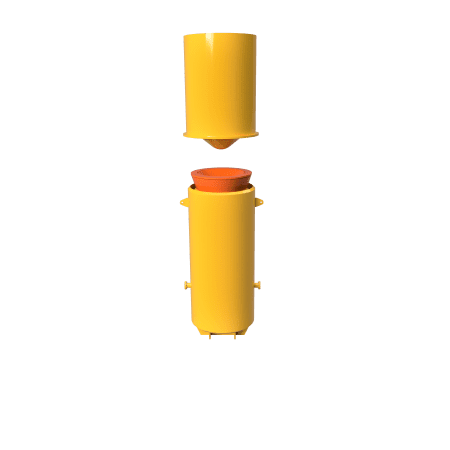

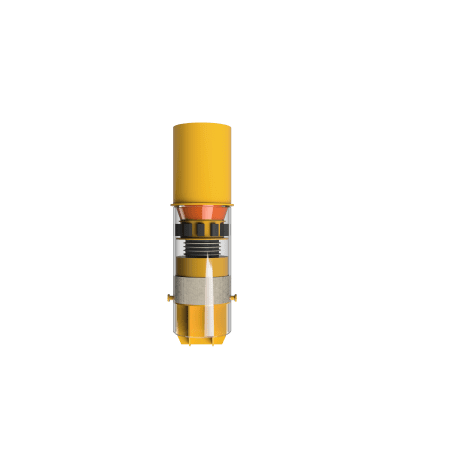

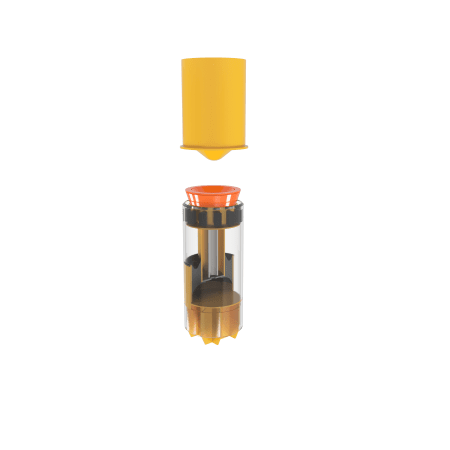

LMU consists of vertical and horizontal rubber elements, especially those formulated to take immense loads with low creep. once the topside load transfer is complete and placed securely on the jacket, the LMU rubber elements are in loaded condition, Sand can be released from the sand release valve, which leads to the plunger assembly being lower, and loads on the rubber element are released.

multiple customization options are possible, like different types of rubber elements depending on the load and application, sand release valves and sand filling chambers, horizontal elastomers, etc.

LMU are fully custom products designed by our in-house design experts individually for every project.

Product Gallery